Our method of concrete moisture testing and determining drying rates is highly accurate.

mr natural® environmental group incorporates the most advanced technology and methods for concrete moisture testing. Excess moisture in concrete is the primary reason for flooring system failures. The cost of testing outweighs the cost of replacing or repairing a flooring system and/or litigation.

You can accurately estimate how much time a concrete slab needs to dry – No. Not with the wrong methods.

Concrete Moisture Testing

Concrete Moisture Testing

There are several methods for testing moisture in concrete and how best to test a slab’s moisture condition, however, others have a high level of inaccuracy and deviation, and therefore predictions are incorrect. An incorrect prediction can offset construction timelines by months ending up in massive cost overruns, scheduling issues and the list goes on. Incorrect measurements can also lead to issues with flooring and environmental conditions such as humidity and mould growth. Concrete moisture testing is considerably less expensive than repairing a flooring system failure, litigation, and the negative impact on reputation.

Test for Moisture Before Installation to Avoid Flooring Failure

Every flooring and general contractor are best served by having a basic understanding of the importance and proper protocol for testing moisture levels in concrete. Without this knowledge, a contractor faces a greater likelihood of flooring failures which may lead to wasted time and financial loss.

All types of flooring are susceptible to failure if moisture conditions are not properly monitored and maintained. When the subfloor is concrete, a moisture problem may begin long before the flooring is installed. If the concrete slab has not been properly dried and cured before the flooring is installed, moisture problems are almost guaranteed. What’s more, moisture-related problems in flooring can also raise health and safety risks resulting from mildew, mould, gaps, bumps and unsecured flooring.

Conditions that Affect Drying Times

As moisture has to move through the concrete to evaporate. The ease of flow through a slab has a significant impact on drying times and this is usually dependent on the unique mixture of the cement, aggregate and other admixtures used. The amount of water used in the mix also impacts how much moisture needs to evaporate.

Environmental or ambient conditions the concrete is poured such as humidity, exposure to the elements, temperature, airflow, additives such as curing compounds, and method of troweling.

Industry Standards

It has been agreed that 72 hours is the minimum sampling time to obtain accurate moisture levels within the concrete. Our method of concrete moisture testing provides accurate measurements within as little as one hour and in 24 hours, is an exact measurement that is dependable and reliable.

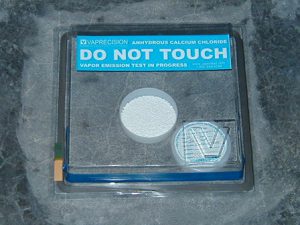

The majority of companies that provide testing are using a flawed system for measuring. This is because different depths will yield different results and in many cases, the difference is significant. Depending on the methods they are using such as surface sensors or Calcium Chloride tests, they usually, can not obtain a reading of more than an inch into the slab or concrete surface. Whilst the highest concentration of the moisture typically remains deeper within the mass, and the surface readings are much lower, the mistake is made in giving the approval to build on top of it or that no vapour barrier is required because it is 3 lbs or less. Further, the majority of testing does not closely follow ASTM F 1869-16 protocols, and there may have significant deviations in their readings. Without a proper understanding of all the variables that can contribute to correct measurements, flooring systems have a higher probability of failure.

Other Reasons for Testing Moisture in Concrete

From time to time, we are contacted by parties involved in a dispute regarding failures with flooring and who is to blame. Many times, neither party even understands the reasons for the failure – Such failures include cupping boards, mould growth, warping, curling or failed adhesion. The moisture level that matters most is the slab’s point of equilibrium. Taking measurements at various depths will yield significantly different results. Based on the wrong measurements, timing or incorrect products are used. The only way to get an accurate, reliable assessment of that moisture condition is by taking measurements deeper within the slab.

Need a better solution? Talk with mr natural about moisture testing for concrete.